Mülheim-Kärlich, Germany, April 11, 2022 – Laserline will present the world’s first blue diode laser with 3 kW CW output power at the Laser World of Photonics 2022 (April 26-29 in Munich). It was especially designed for welding, cladding and additive manufacturing of copper components. It is a further milestone in the power development of blue high-power diode lasers. The second key topic of the exhibition presentation is the new high-power-cladding-solution based on a 45 kW IR diode laser. This was developed in cooperation with the Fraunhofer Institute for Material and Beam Technology (IWS). This high-power-cladding-solution is meant to optimize the industrial cladding of components that are subject to wear and corrosion.

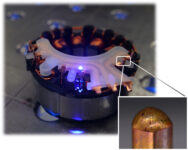

Blue 3 kW diode laser allows a more effective and energy-efficient copper processing

Back in 2019, Laserline had already presented the world’s first blue CW diode laser with up to 1 kW CW output power, whose power was subsequently raised to 2 kW just a year later. The blue 3 kW diode laser that is now being showcased in Munich displays the highest performance class of industrial lasers in the blue wavelength spectrum to date. In line with the 1 and 2 kW Laserline diode lasers, the new laser operates at a wavelength of around 445 nm. This spectral range is absorbed much better by non-ferrous metals such as copper and gold compared to infrared radiation. Among other benefits, this allows the heat conduction welding of copper components close to the surface, along with more energy-efficient and climate-friendly processes. Increasing the CW output power to 3 kW now makes it possible to have additional application options. In joining and cladding processes, much faster welds and higher deposition rates can be achieved. In the case of keyhole welding of electrical conductors such as copper hairpins, larger cross-sections can be handled with moderate heat input using blue lasers only. Where hybrid solutions combining blue and infrared lasers continue to be required, less infrared energy is needed today. This clearly optimizes the operation costs and the CO2 balance of the applications. Furthermore, the new laser power class enables a more efficient additive manufacturing of large and volume-rich copper components. At the Laserline booth, these new application possibilities will be discussed in detail before being demonstrated with the help of different welding and cladding samples.

Cladding with up to 45 kW laser power: higher order rates – bigger quantity

The presented high-power-cladding-solution shows the next expansion level of a method that was successfully established by Fraunhofer IWS using the Laserline IR diode laser with 20 kW output power. In some cases it even exceeds the application rates in PTA (Plasma Transferred Arc) cladding. Being the first process of its kind, it enables wear and corrosion protection coatings for large components such as power plant elements, brake discs, hydraulic cylinders or plain bearings to be readily implemented for series-production and in a cost-effective manner. Access to the use of a higher diode laser power class with up to 45 kW output power further increases the efficiency and productivity of the process. This enables higher order rates and larger quantities at reduced process costs. The solution and its benefits will be demonstrated at the booth using a 45 kW IR diode laser. Furthermore, videos, animated illustrations of powder-based laser cladding processes and samples of cladded components are going to be presented.

Anyone interested will find Laserline in Hall A5, Booth 305. More information about the high-power-cladding-solution and its system requirements is also available from the Fraunhofer IWS at the Fraunhofer joint booth in Hall A6, Booth 441.