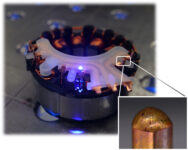

Mülheim-Kärlich, September 09, 2021 – Laserline, the leading international developer and manufacturer of diode lasers for industrial material processing, will exhibit some new approaches to the digitalization of diode laser-based joining processes at Schweisstec 2021 (October 26-29, 2021 in Stuttgart, Germany). The focus of this trade show appearance is a new development phase in the Industry 4.0-oriented Digital Laser Solutions from Laserline, i.e. the digital control of processing optics with a multi-spot module. This was developed by Laserline in close collaboration with two technology partners. The modules make it possible to implement brazing and welding processes based on highly individualized spot geometries and intensity distributions with high positional accuracy. For example, a triple-spot process can be implemented for the brazing of hot-dip galvanized sheet. In this process, two smaller pre-spots remove the zinc coating in the seam area and thus effectively calm the brazing process. In welding processes, a spot-in-spot configuration, in which a narrowly focused inner spot is overlaid with a larger rectangular spot, can achieve a significant improvement in gap bridgeability. In these and other constellations, spot geometry, positioning and energy distribution within the spots can be flexibly adapted while the process is in motion.

The digital control of modular optics presented at Schweisstec further optimizes the use of multi-spot technology. It also supports the full integration of laser and optics in a digital system control. As with the beam sources, this integration and control are made possible via OPC UA and MQTT interfaces in the optics unit. The desired spot parameters can thus be programmed and monitored for all phases of the process via a central digital control unit. Among others, this provides an Industry 4.0 complete solution for production lines in the automotive sector that optimally supports a fully comprehensive integration of the laser systems into a digitized process control. In addition to multi-spot modular optics, the digital control option is also available for Laserline zoom optics. For example, it can open significant optimization potential for wide-beam applications in hardening or cladding.

Those interested should find Laserline in hall 7, booth 7307. You may also find more detailed information about the multi-spot optics and digital integration of the Laserline diode lasers online at https://www.laserline.com/en-int/multi-spot-optics/ and https://www.laserline.com/en-int/lasers-meet-digitalization/