Mülheim-Kärlich, August 01, 2023 – The standard process for drying battery electrodes has long been convection drying in gas or electricity-powered conveyor ovens. However, with ambitious climate protection targets and rising energy prices making this process progressively unattractive, battery manufacturers are therefore increasingly looking for alternatives. So far these comprise either of improvements to established processes or completely new methods such as dry coating or vacuum coating. The former has been championed by Tesla as a viable process for the future and is at least theoretically capable of overcoming some of the fundamental limitations of battery cell production. However, serial implementation is technologically extremely demanding and is additionally restricted by various patent claims.

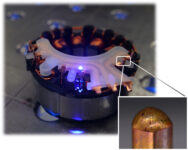

Against this background an innovative laser drying process for the low-emission and economical series production of lithium-ion batteries has been developed as part of the IDEEL project (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production). Already two years into the project, it draws on Laserline’s high-power diode lasers to, for the first time, enable the production of anodes and cathodes in a roll-to-roll process, and, with operating cost savings of 30 percent and a halving of the required production area, is a milestone on the way to CO2-neutral and competitive battery cell production. Several major battery and automotive manufacturers are currently qualifying the process in pilot production runs and industrial implementation on a broad front is expected from 2024 at the latest.

More detailed information on the design and advantages of the new process can be found in the white paper ‘Diode Laser Drying of Electrodes for Lithium-Ion Batteries’, authored jointly by Laserline experts and staff from the PEM group. The white paper is available for free download here.