Mülheim-Kärlich, 28.09.2018 – Laserline, the international leading developer and manufacturer of high-power diode lasers, will exhibit at EuroBLECH 2018 (23rd to 26th October in Hanover; Hall 16, Booth G19) its laser systems for industrial material processings such as joining, cladding and hardening. The highlight of this exhibition presentation will be the fiber coupled mobile diode lasers of the LDF series that make output powers of up to 25 kW available in different system configurations. To be presented are, inter alia, the versatile used LDF 11000-60 with 11 kW output power and 60 mm mrad beam quality that is used for metal processing as well as the classic 5 kW welding laser LDF 5000-30. Also on board is the converter laser LDF 6000-6 that combines high output power (6 kW) with elevated brilliance (6 mm mrad beam quality). It was specifically designed for high-power applications with raised demand on the beam quality such as remote welding.

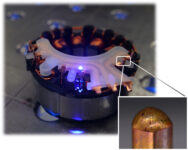

A further highlight of the presentation is the blue diode laser LDM 500-60blue for the 19” integration which works with a wavelength of 450 nm. It was developed within the EFFILAS support measure of the Federal Ministry for Education and Research (BMBF) in close collaboration with OSRAM and other project partners. Its absorption is seven to twenty times higher than that of infrared lasers, which enables a controlled heat conduction welding of nonferrous metals. In particular, new production methods of electrical contacting benefit from this (e.g. in battery and rechargeable battery production). From the LDM modules series designed for the 19‘‘ rack, Laserline presents the LDM 6000-100 which can, inter alia, be used for brazing roof seams in the automotive sector. Like all LDM modules, it contains the laser head, cooling, power supply and system electronic, and can moreover be integrated easily and save up on space in production plants.

Besides the beam sources, Laserline will also present at EuroBLECH special processing optics for many different application fields, e.g. an OTS-5 brazing and welding optic. This has a multi-spot module that received the Innovation Award Laser Technology 2018 and which supports, inter alia, triple spot brazing and aluminum welding with triple spot. To be additionally shown is an OTS-5 cladding optic with the Coax 11 broad beam nozzle for generating higher order rates. The presentation will be rounded off by selected exhibits from different application fields, e.g. the door of an Audi of the A-series and a sample for the welding of tailored blanks.